There are some factors affecting the efficiency of agitating some are related to the liquid characteristics such as viscosity and density, and some are related to the geometry such as the container diameter (D), impeller length (Y), rotating speed (N), height of impellers from bottom of the container (h) as shown in Figure 1.2, the later affects the gathered materials in the bottom of the container because this amount can't be minimized to a great value as it demands a high capacity of the motor due to surface tension of the liquid. Agitation has various purposes such suspending solid particles, blending miscible liquids, dispersing a gas through a liquid in the form of small bubbles, dispersing a second liquid immiscible with the first, to form an emulsion or suspension of fine drops, and promoting heat transfer between the liquid and a coil or jacket. Cavitations lead to lowering the agitating efficiency due to storing a great amount of energy in the form of pressure. These agitators cause bubbles in the liquid of the liquid vapor called Cavitations. In addition, the classical agitator generate bubbles inside the gas causing dribble which is prohibited in liquids of low flash points. Most agitator cause vortex in the center of the liquid which enforces the manufacturers to put Baffles inside the agitating tanks.

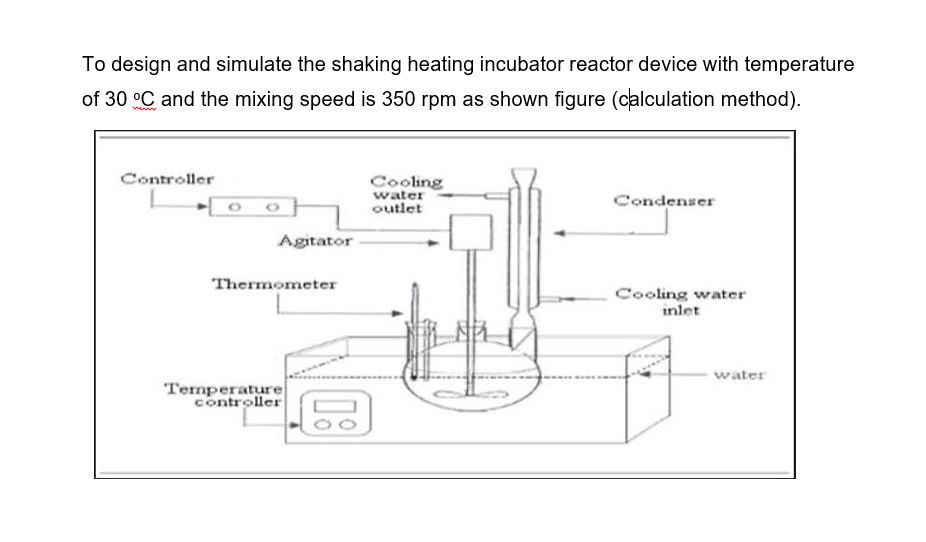

In spite that agitator is very effective in industry today but still has many problems which affect the agitation process. Generally, agitation refers to forcing a fluid by agitator means to flow in a circulatory or other pattern inside a vessel (see Figure 1.1). In the chemical and other processing industries, many operations are dependent to a great extent on effective agitation and mixing of fluids.

Introduction Agitation is the process of induce motion of material in a specified way. The study ended up with conclusions to maximize agitator performance and optimize the geometrical parameters to be used for manufacturing the differential agitator.ġ. In addition, the experimental work has been done to express the internal container shape in the agitation efficiency. Knowing the material prosperities and the loading conditions, the FEM using ANSYS11 was used to get the optimum design of the geometrical parameters of the differential agitator elements while the experimental test was performed to validate the advantages of the differential agitators to give a high agitation performance of lime in the water as an example. A numerical analysis, manufacturing and laboratory experiments were conducted to design and implement the differential agitator. For improving efficiency, parametric study and shape optimization has been carried out. Then, the liquid moves to the so high pressure area under the agitating group causing the liquid to exit from the square directors in the bottom of the container. The agitating process occurs through the agitating group bearing causing a lower pressure over the upper group leading to withdrawing the liquid from the square directors of the liquid entering and consequently the liquid moves to the denser place under the quartet upper group. The fixing group is installed containing the agitating group inside any tank whether from upper or lower position. The agitating group is located inside a cylindrical container equipped especially to contain square directors for the liquid entrance and square directors called fixing group for the liquid exit. The first shaft is the bearing axis while the second shaft is the axis of the quartet upper bearing impellers group and the triple lower group which are called as agitating group. The Differential Agitator is an electro- mechanic set consists of two shafts. This research is to design and implement a new kind of agitators called differential agitator.

0 kommentar(er)

0 kommentar(er)